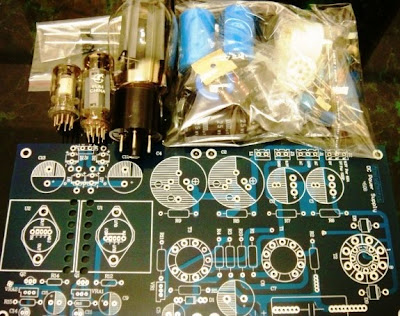

Features

Features1.

High voltage output voltage: 50V - 400V DC up to 100mA

2.

Low voltage output voltage: 0-30V up to 5A

3. High power BJT switch

E13005 and regulators

LM1085 and

LM10844. Output voltages can be adjusted by two resistor trimmers

5. Three

BHC audio capacitor 100uF/450V and

WIMA 100nF/450V for high voltage decoupling capacitors.

6. Two

BHC audio capacitor 10000uF/63V for low voltage ripple decoupling capacitors.

7. Dedicated ground and power rails layout design

8. Lowpass filter with optional inductor 10H 100mA.

9. PCB dimension: 154mm x 98mm

Required power supply:

For HV regulator: 200/220/240/260/280/300V AC / 100mA

For LV regulator: 12/15/18V AC / 1-5A

Optional T30 toroidal transformer:

Schematic and Layout

Schematic and Layout

ASSEMBLY GUIDEPrecaution:

ASSEMBLY GUIDEPrecaution: 1. Do not use any body parts to touch the metal parts of the kit after power up or power off, since the high voltage capacitors may not fully discharge. It may cause serious electric shock.

2. Use a power transformer with fuse (1-3A) socket to limit the supply current in case of short circuit or incorrect assembly.

3. Double check the assembled components with the schematics.

4. Do not attempt the measure the voltage by multimeter with hand after power up. The probes of the multimeter should be mounted by some stands to the points of the measurement before switching on the power supply.

5. Turn off the power supply if you observe any smokes or hear strange sound coming out from the transformer or board. If there is short circuit, the transformer will be getting very hot shortly.

Procedures.1. Solder all the resistors and two blue resistor trimmers 1k (102) and 5k(502) according to the schematic and part list. The biggest resistor is 5W, whereas smaller one is 2W.

2. Solder two diodes 1N4007 and Zener diode (1N4733A). Notice the direction of the diodes and Zener diode. There are white bar marked in board corresponding to the bar of the components. The Zener diode looks similar to the silicon diode (standard diode). However, their operation direction of current flow is totally different. The Zener diode is slightly smaller than the diodes. In the photo, the Zener diode is displayed as orange in color with dark line.

3. Mount the power BJT M13005, regulators LM1085/LT1085 and LM1084 to the heat sinks by the provide screws and nuts. Their packages are idential, however do not mix up the BJT with the regulators. It will cause the voltage breakdown of the regulator.

4. Solder the high voltage capacitors 100uF/450V and low voltage capacitors 10000uF/63V. Be care of the polarity of the capacitors. There have a "+" marked in PCB for indicating the positive pin.

5. Solder the remaining components.

6. Connect optional inductor 10H 100mA for further attenuation of the the ripply voltage or leave it unconnected.

6. Apply 200/220/240/260/280/300V AC to the connector (Blue) to the high voltage regulator and 12/15/18/24/27V AC to the connector (Blue) of the low voltage regulator as shown in the below photo.

7. For higher output voltage, apply higher AC voltage to the board. For example, 300V AC to produce output voltage 100-400V or 220V AC to produce output voltage in range from 50- 280V DC. To allow high efficiency of the regulator, the difference between the output voltage to input voltage should be small. Otherwise, much of input power will be dissipated in form of heat.

8. For high voltage module, the output current is limited by the resistor R1 (1K ohm 5W). To increase the output current, the resistor R1 should be decrease. The recommended range is 10-1K Ohm.

Checklist:

Checklist:1. The direction of diodes and Zener diodes.

2. The polarity of the high voltage capacitors.

3. The correct assembling of diodes, Zener diodes, high voltage capacitor, power BJT and regulators.